360CNC

Our DMG Mori Seiki 5-Axis Milling Machines combined with custom software and a precision controller give us unparalleled capability when it comes to milling 360 degrees to produce a complete club head.

Pure Tempered

When the golf club is firmer in certain areas spin performance and feel greatly improves our proprietary tempering process is started at 850 degrees for 4 hours then we cool it down to 500 degrees in a specialized vacuum atmosphere.

3D-CG

Our center of gravity height and depth is optimized with the help of advanced computer aided design then verified with human testing. The consistency of our CG placements is consistent through every club.

Made in Japan

All of SEVENs materials, manufacturing to finish is done 100% in Japan using golf dedicated suppliers and crafters.

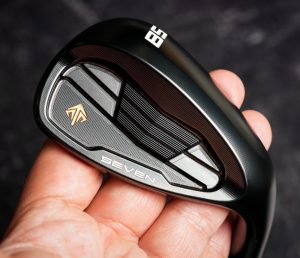

SEVEN NEO IRON

The SEVEN NEO is a true blade in every sense, but with a revolutionary twist. By adding two compact cavities, we've positioned weight outward, dramatically increasing perimeter stability and creating a larger sweet spot. This innovative design gives you the shot-shaping control of a blade while offering the forgiveness you’d expect from a cavity-back iron.

SEVEN MCB IRON

Only 6 sets are made each month (maximum) and a few months a year no sets are produced. As of now, there is a 6-8+ month waitlist on many of their models, this is not a covid or supply chain issue but rather the nature of the beast when each iron head takes 14-17 hours to mill.

SEVEN MB IRON

SEVEN NEO PUTTER

SEVEN CB IRON

SEVEN SC IRON

SEVEN ARROW PUTTER

SEVEN is making the highest end products in golf today.